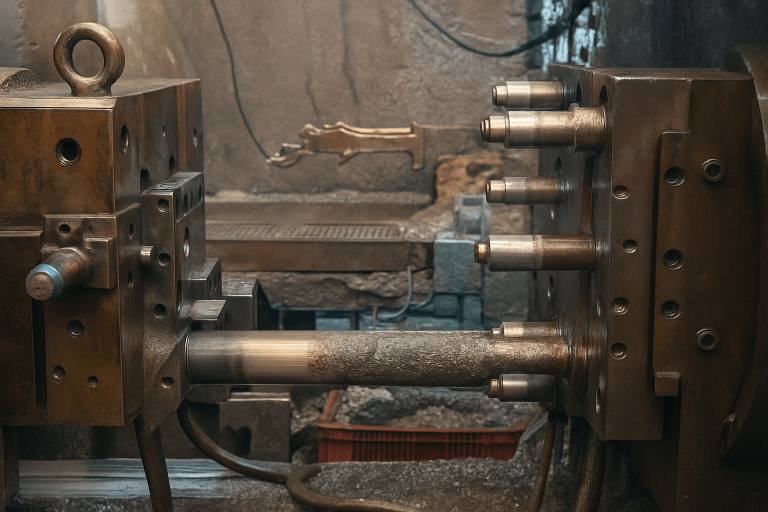

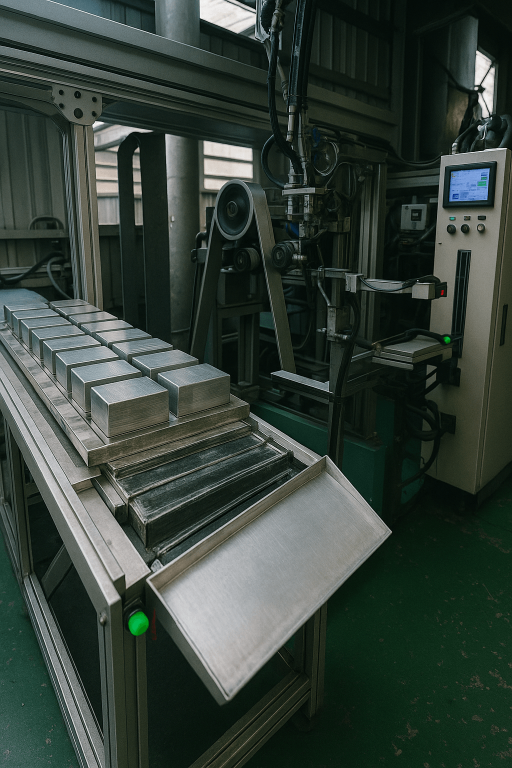

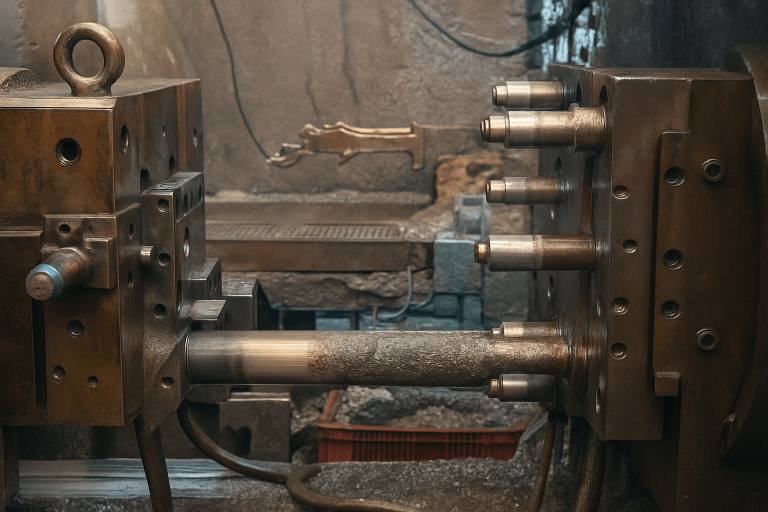

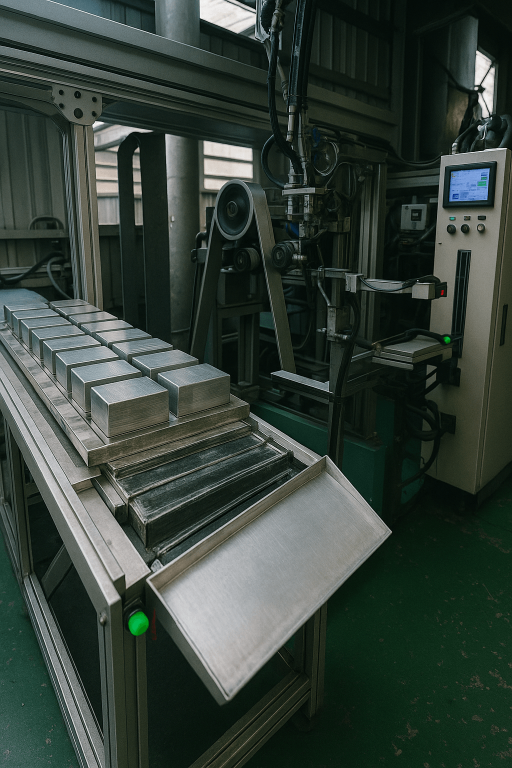

In the production process, molten metals (such as aluminum and zinc) are injected into molds under high pressure, with a focus on high-quality products. This further improves product quality and precision, while achieving even better mechanical properties. We use high-quality machines to ensure the consistency and continuity of each batch of products.

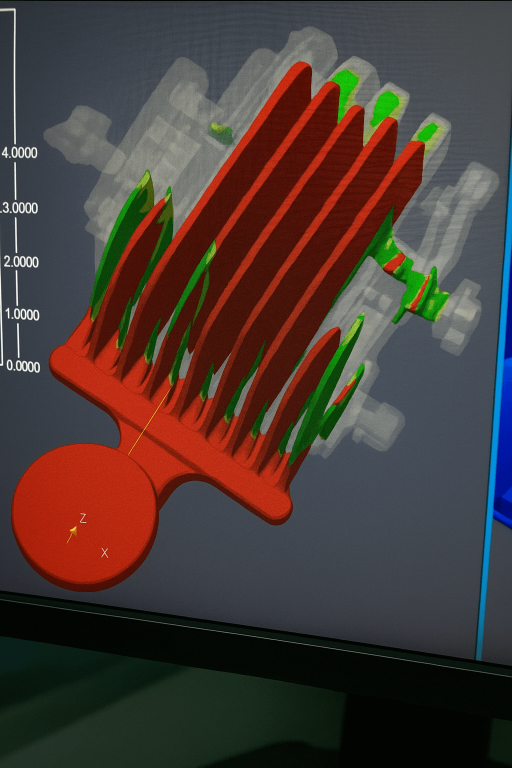

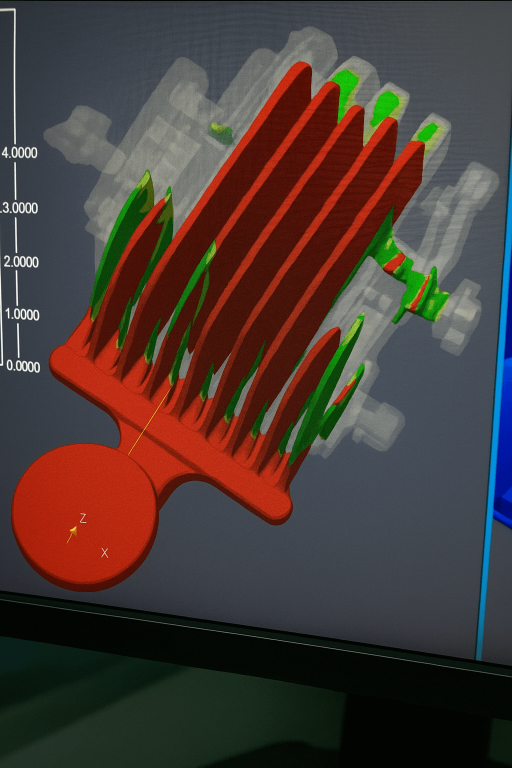

Based on the specific needs and product designs of customers, our professional design team first develops precise molds. Mold design is the cornerstone of the entire manufacturing process, determining the shape, size, and quality of products. We use advanced design software for mold development to ensure that every detail meets relevant standards, thereby improving product reliability and consistency.

As the final step, all conforming products are meticulously packaged and delivered to customers on schedule. We use high-quality packaging materials and advanced packaging technology to ensure that products are not damaged during transportation. We also provide a variety of packaging solutions, customized to customer needs, to ensure products arrive safely at their destination.

Upon completion of all production procedures, we conduct a pre-shipment inspection according to operating standards. This includes a comprehensive inspection of the product's appearance, size, and performance to ensure that it meets the customer's requirements and standards. Our quality inspection team checks every detail to ensure that only conforming products are delivered to customers.

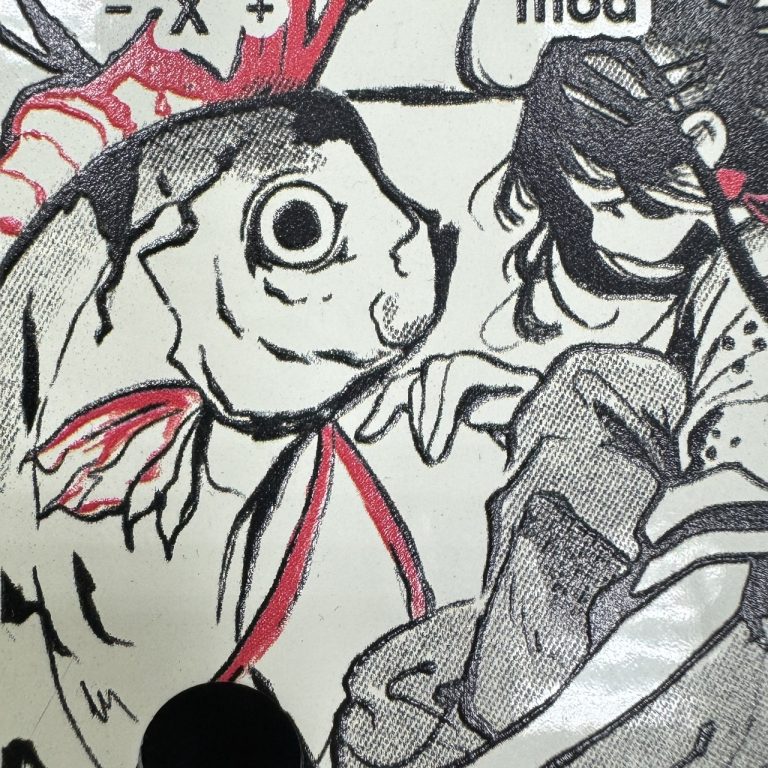

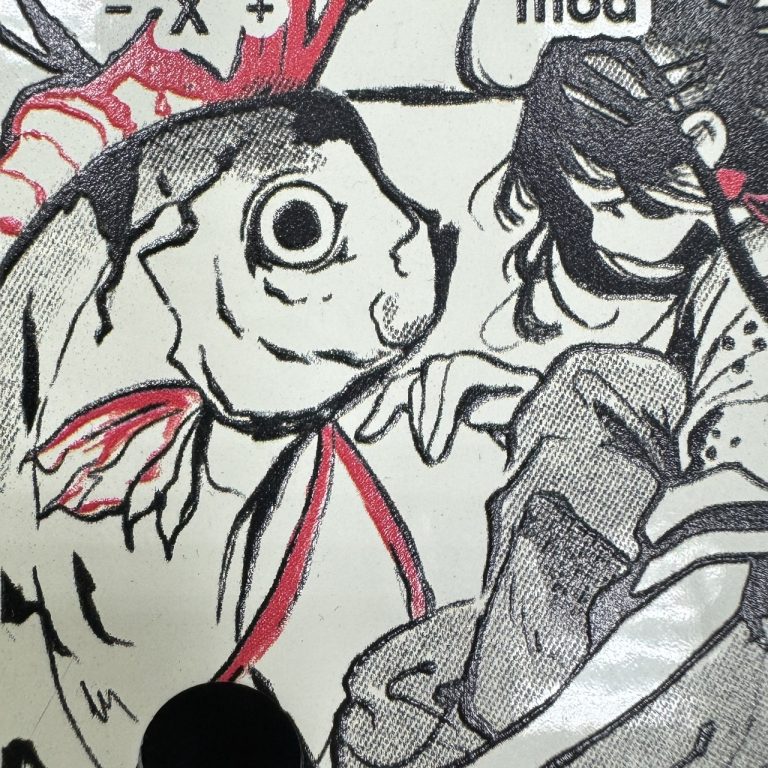

We print standards, graphics, or text on product surfaces according to customer requirements, thereby personalizing products and enhancing brand recognition. We use high-quality printing technology to ensure that the passion and durability of the printed content will not fade or become obsolete due to use or washing.

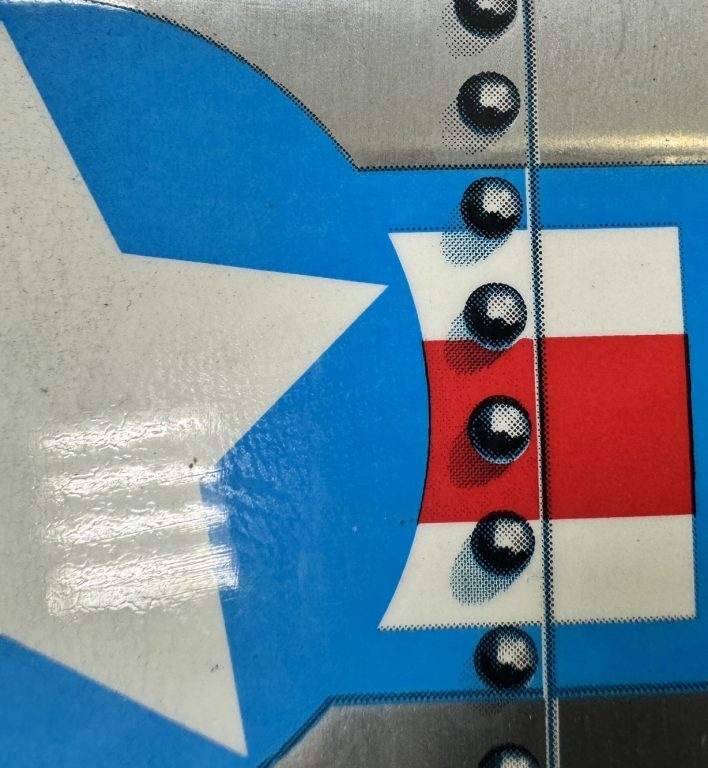

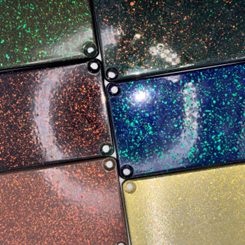

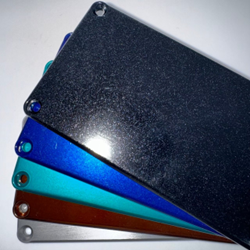

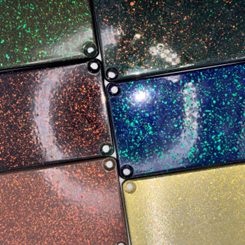

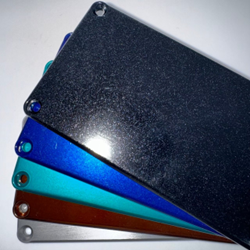

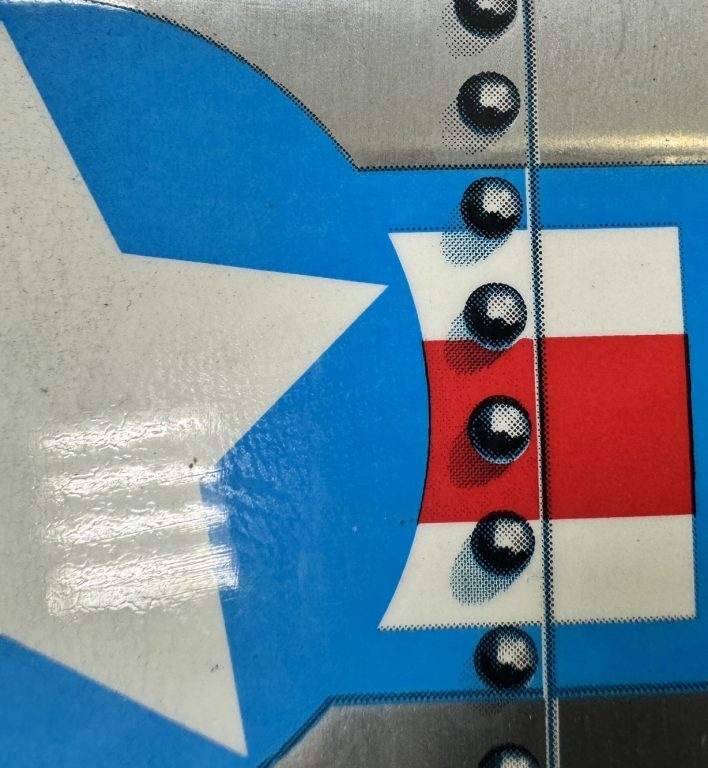

We cover the surface of products with one or multiple layers of durable paint to further improve the durability and appearance of our products. The paint adds to the tone and gloss of products, and provides a thick layer of exterior protection to effectively prevent marks and rot. We use eco-friendly coating materials and advanced covering technology to ensure high quality products that are friendly to the environment.

After processing, we apply a variety of surface treatments to the products. These treatments not only enhance their aesthetic appeal but also improve their corrosion resistance and extend their service life. Based on customer needs, we select the most suitable surface treatment method, ensuring products achieve both an appealing appearance and excellent performance.

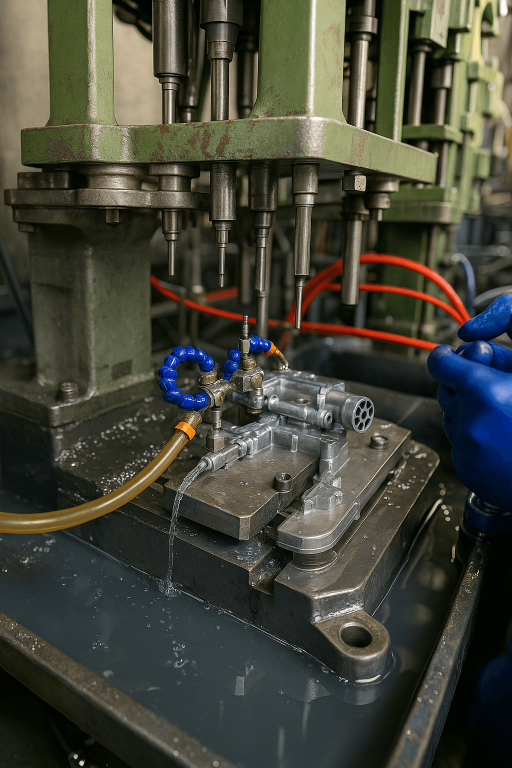

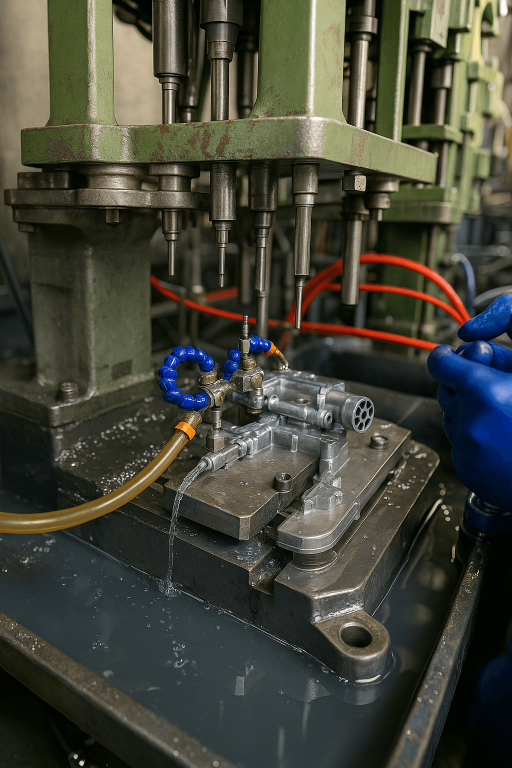

After burrs are removed, the product enters the processing stage, which includes five-axis CNC, cutting, grinding, and drilling, to achieve the specifications and dimensions of the finished product. With an experienced processing team and advanced equipment, we can meet diverse processing requirements, ensuring both high precision and high quality in our products.

Some burrs and residual materials may appear on the product surface during processing. Our burr treatment process uses specialized equipment and technology to remove these burrs and make the product surface flat and smooth, laying a good foundation for subsequent processing and surface treatment.

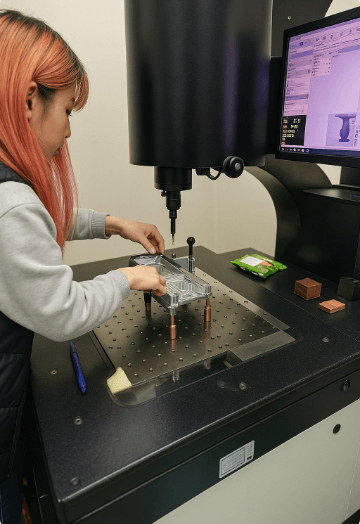

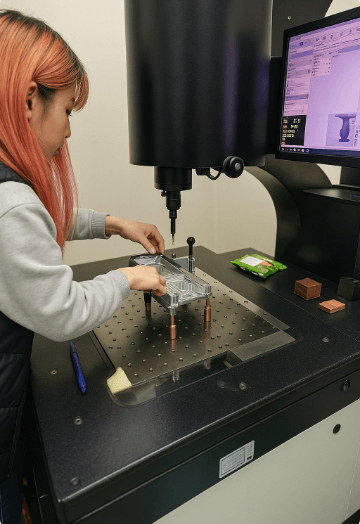

After manufacturing, we perform measurement-based quality inspections and precision measurement control. We use high-precision inspection instruments to inspect the size, shape, and structure of products, in order to ensure that they meet design specifications and quality standards. If there is any deviation, we will make timely adjustments and modifications to ensure the smooth execution of subsequent work.

Based on the specific needs and product designs of customers, our professional design team first develops precise molds. Mold design is the cornerstone of the entire manufacturing process, determining the shape, size, and quality of products. We use advanced design software for mold development to ensure that every detail meets relevant standards, thereby improving product reliability and consistency.

In the production process, molten metals (such as aluminum and zinc) are injected into molds under high pressure, with a focus on high-quality products. This further improves product quality and precision, while achieving even better mechanical properties. We use high-quality machines to ensure the consistency and continuity of each batch of products.

After manufacturing, we perform measurement-based quality inspections and precision measurement control. We use high-precision inspection instruments to inspect the size, shape, and structure of products, in order to ensure that they meet design specifications and quality standards. If there is any deviation, we will make timely adjustments and modifications to ensure the smooth execution of subsequent work.

Some burrs and residual materials may appear on the product surface during processing. Our burr treatment process uses specialized equipment and technology to remove these burrs and make the product surface flat and smooth, laying a good foundation for subsequent processing and surface treatment.

After burrs are removed, the product enters the processing stage, which includes five-axis CNC, cutting, grinding, and drilling, to achieve the specifications and dimensions of the finished product. With an experienced processing team and advanced equipment, we can meet diverse processing requirements, ensuring both high precision and high quality in our products.

After processing, we apply a variety of surface treatments to the products. These treatments not only enhance their aesthetic appeal but also improve their corrosion resistance and extend their service life. Based on customer needs, we select the most suitable surface treatment method, ensuring products achieve both an appealing appearance and excellent performance.

We cover the surface of products with one or multiple layers of durable paint to further improve the durability and appearance of our products. The paint adds to the tone and gloss of products, and provides a thick layer of exterior protection to effectively prevent marks and rot. We use eco-friendly coating materials and advanced covering technology to ensure high quality products that are friendly to the environment.

We print standards, graphics, or text on product surfaces according to customer requirements, thereby personalizing products and enhancing brand recognition. We use high-quality printing technology to ensure that the passion and durability of the printed content will not fade or become obsolete due to use or washing.

Upon completion of all production procedures, we conduct a pre-shipment inspection according to operating standards. This includes a comprehensive inspection of the product’s appearance, size, and performance to ensure that it meets the customer’s requirements and standards. Our quality inspection team checks every detail to ensure that only conforming products are delivered to customers.

As the final step, all conforming products are meticulously packaged and delivered to customers on schedule. We use high-quality packaging materials and advanced packaging technology to ensure that products are not damaged during transportation. We also provide a variety of packaging solutions, customized to customer needs, to ensure products arrive safely at their destination.

32647

No. 16, Alley 30, Lane 236, Heping Road, Yangmei District, Taoyuan City

TEL:03-485-5561

FAX:03-4356103

MAIL:chichao.ad@gmail.com